Description of plasma arc welding process

What is plasmal arc welding?

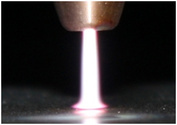

In plasma welding, the welding or main arc as well as in TIG welding, burns between the tungsten electrode and the workpiece. In addition, a so-called "pilot arc" with a current intensity of 3 - 30 A burns between the tungsten electrode and an intensively water-cooled nozzle. A plasma gas, usually argon, is additionally passed between the electrode and the nozzle. This pushes the pilot arc slightly out of the nozzle so that it can be seen as an ionizing "flame". The pilot arc ionizes the arcing path, and the main arc can now be ignited without high-frequency contact with extremely high reliability. The constriction of the arc, characteristic of plasma welding, is achieved by various physical effects (cooling effect of the nozzle, electromagnetic effects).

The melt bath is protected by the protective gas supplied between the outer protective gas nozzle and the plasma nozzle. Pure Argon or gas mixtures with hydrogen or helium can be used as protective gas.

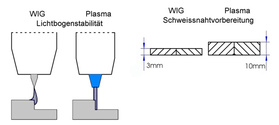

The plasma arc has a significantly higher energy density and a lower beam divergence compared to the other conventional arc welding methods. While the diameter of the TIG arc increases with an angle of 45° from the electrode tip to the workpiece, the diameter of the plasma arc is only slightly increased and is formed like a column.

How is the plasma welding process different from other welding processes?

- High stability of the arc column

- Narrow arc column, independent of the distance between the torch workpiece

- Improved weldability for materials with edge misalignment

- Narrow seam width

- Low distortion

- Low weld reinforcement

- Higher welding speed than TIG welding

- Reliable ignition of the arc

- Very good reproducibility of welding in automatic systems

- Exactly adjustable welding depth

- Spatter-free welding process

- Higher tolerances possible than with the laser

- Electrode is protected against contamination (oil, zinc,..)

- Life time of electrode is up to 30 times higher than TIG welding

The plasma welding process is divided into several areas, depending on the application and requirements:

- Micro Plasma Welding

- (Soft-) Plasma Welding

- Plasma Short-time Welding

- Plasma Spot Welding

- Plasma Keyhole Welding

- Plasma Soldering

The procedural principles described above apply here largely to all subdivisions.

Further information

Procedural principle

- Description of plasma arc welding process

- Micro plasma welding

- Plasma Welding

- Plasma short-time welding

- Plasma spot welding

- Plasma keyhole welding

- Plasma soldering